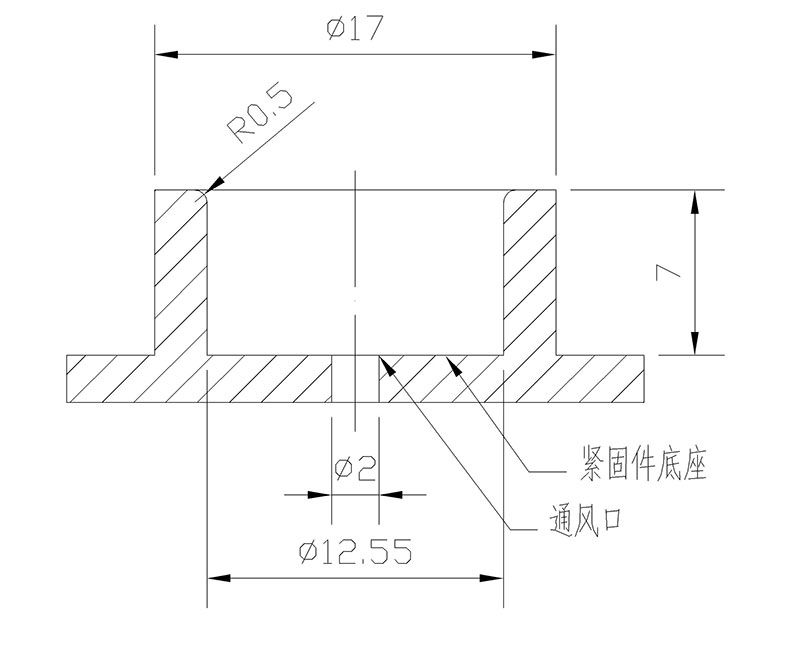

| Airflow: | 3.5l/min@1.2Kpa |

| WEP: | >0.5bar |

| Vent Membrane Material: | ePTFE |

| Vent Membrane Features: | Waterproof,Dustproof,Breathable |

| Vent Membrane Color: | White |

| Temperature: | -40℃~125℃ |

| Body Material: | HDPE |

What are the main applications of waterproof and breathable vent plugs?

At present, it is mainly used in automobile parts and other fields.

How to choose waterproof vent plugs correctly?

The selection of waterproof air permeable plug is related to the use direction, working temperature, installation size, air permeability requirements, protection requirements, etc. Please consult the sales staff of the company.

What is the air permeability of the waterproof vent plug?

The air permeability is determined by the material of waterproof breathable vent membrane, the effective ventilation area and the difference between inside and outside pressure.

How to test the performance of waterproof vent plugs?

Waterproof and air permeability performance have professional equipment testing, simple testing methods can consult company sales staff.

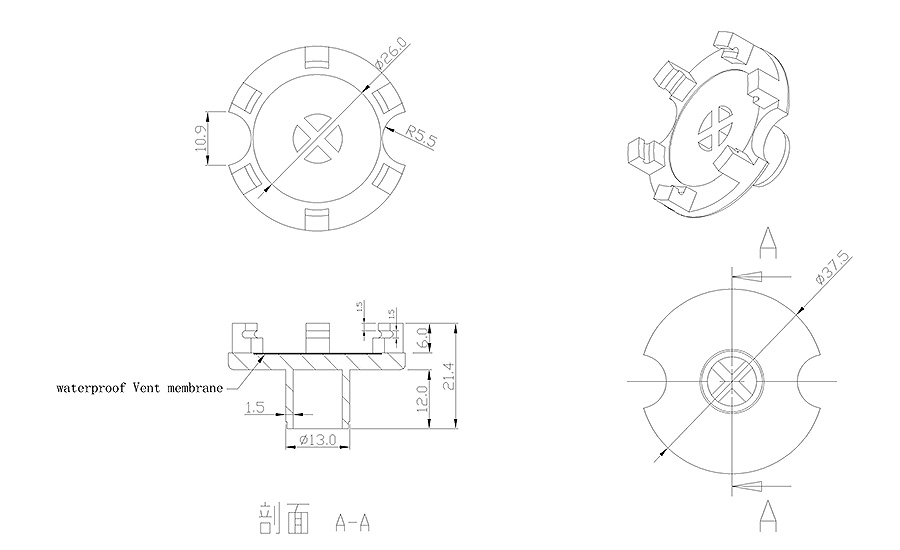

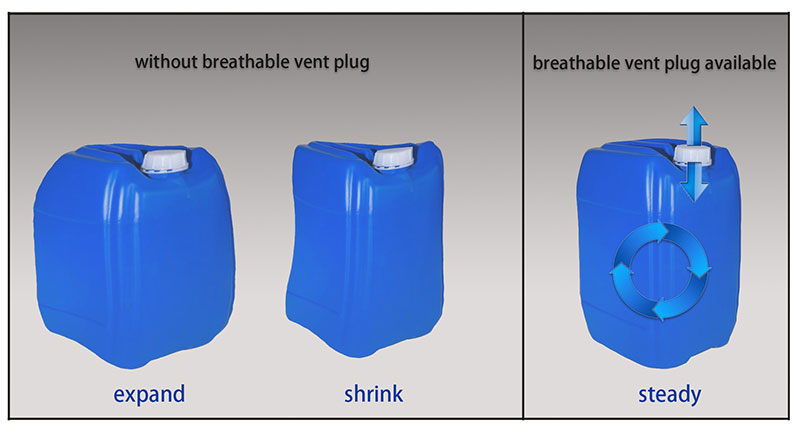

For the container cover with holes, the gas will pass through the porous expanded polytetrafluoroethylene (ePTFE) permeable film and escape through the holes on the container cover, while preventing the liquid and particles from entering the packaging. The porous expanded polytetrafluoroethylene (ePTFE) permeable membrane prevents pressure accumulation by continuously balancing the pressure difference between the internal and external environment of the container.

For the non-porous container cover, the gas will pass through the porous expanded polytetrafluoroethylene (ePTFE) permeable film to reach the area above the permeable film, and then be guided to the screw position of the container cover to escape, while preventing the liquid and particles from entering the packaging. The porous expanded polytetrafluoroethylene (ePTFE) permeable membrane prevents pressure accumulation by continuously balancing the pressure difference between the internal and external environment of the container.

Product installation and description

1. avoid contact with sharp objects, do not touch or squeeze film.

2. wear gloves or fingernails during the operation.

3. do not wash or reuse.