| Airflow: | 2200ml/min/cm2@7kpa |

| IP Rate: | IP67 |

| Vent Membrane Material: | ePTFE |

| Vent Membrane Features: | Waterproof,Breathable,Dustproof |

| Body Color: | White |

| Temperature: | -40℃~110℃ |

| Adhesive Material: | crylic acid |

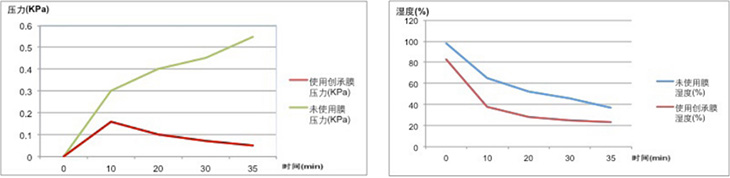

1. After 30 minutes of lighting, the humidity of unused waterproof permeable film is 98%, and that of using innovative waterproof permeable film is 82%.

2. After turning out the lamp, after 35 minutes, the humidity of the non-used waterproof permeable film decreased to 37%, and that of the use of the innovative waterproof permeable film decreased to 23%.

What are the main applications of waterproof breathable vent membrane?

At present, it is mainly used in automobile parts, outdoor lighting, communication equipment, pesticide chemical packaging, plant protection tissue culture, connectors, new energy and other fields.

How to choose waterproof and breathable vent membrane correctly?

The selection of waterproof permeable film is related to the use direction, working temperature, installation size, permeability requirements, protection requirements, etc. Please consult the sales staff of the company.

What is the air permeability of waterproof breathable vent membrane?

The air permeability is determined by the material of waterproof breathable vent membrane, the effective ventilation area and the difference between inside and outside pressure.

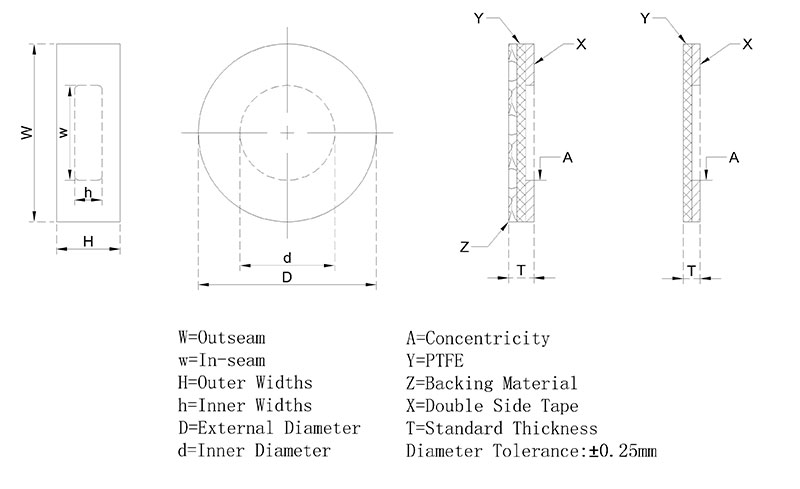

Can the size of the product be customized?

It can be customized according to the drawing requirements.

How can we leak water after testing the waterproof breathable vent membrane?

1. test conditions exceed product performance.

2. Back glue is not completely stable after testing. It is recommended to do the test after 36 hours.

3. Back glue bonding is not reliable, the workpiece bonding surface has not been cleaned up with dust or grease stains, the bonding surface has pits, bulges, cracks and so on.

4. The other parts of the workpiece are not well sealed. It is suggested that the air permeability should be blocked first, the air tightness of other parts should be verified first, and then the film test should be affixed after confirming the correctness.

How to install waterproof breathable vent membrane:

- ensure waterproof, breathable products and shell temperatures above 10 C.

- Use waterproof and breathable products, wear gloves or use round-headed tweezers to avoid direct contact with sharp objects waterproof and breathable products.

- the installation surfaces shall be clean, oil-free, particulate and other contaminants.

Waterproof and breathable products should be installed on flat, vertical surfaces so that liquids or other pollutants do not accumulate.

When using the automatic installation machine, please follow the instructions of the machine.

For manually installed products, roll the release paper under the waterproof and breathable product until the product is peeled off from the release paper to a state of easy pickup.

Try to avoid prying products or folding products from the release paper, or they may damage the product.